Injectors

STEAM JET SUCTION PUMP (RESTARTING INJECTOR)

These restarting injectors were and are widely used on all types of stationary steam plant and in particular for cab operation in locomotives of all gauges and traction engines. These injectors stand out from competitors products from their reliability and extraordinary simplicity along with exceptional quality and price.

The injectors are made by a family-owned company in the north of Italy with long-standing experience in the sector. The pumps comply with the requirements of EU Directive VII 97/23/EC (PED) and are certified at the moment of delivery.

In this way the old steam jet pumps, often subject to irreparable wear, can be replaced by new parts characterized by functional safety and winning design (respecting the development of the technology).

Each single part can be purchased as a spare part.

Functioning

By opening the steam throttle lever, the steam enters the nozzle, reduces its pressure below atmospheric and increases its speed to sonic or supersonic.

Fresh water is taken in and mixes with the steam. As the steam condenses, it greatly reduces in volume, creating a vacuum which draws more feed water into the convergent combining cone.

The pressure drop created, closes the check valve avoiding air inlet.

The condensate mixture then enters a divergent delivery cone.

Here the water expands changing the velocity energy into pressure energy and opens the non return valve exceeding the pressure of the boiler.

An overflow is required for excess steam or water to discharge, especially during starting.

Characteristics

Body is in black painted cast iron (high temperatures resistant); nozzles, cones, and internal parts in bronze; steam throttle lever in brass.

Operating Pressures & Models

Model PN 16 from 58 to 174 psi (4-12 bar) PN 25 from 87 to 232 psi (6-16 bar) operating pressure Both models are available in sizes 4 (only model PN 16), 5, 6, 8, 10, 12 and 15, depending on the required flow rate.

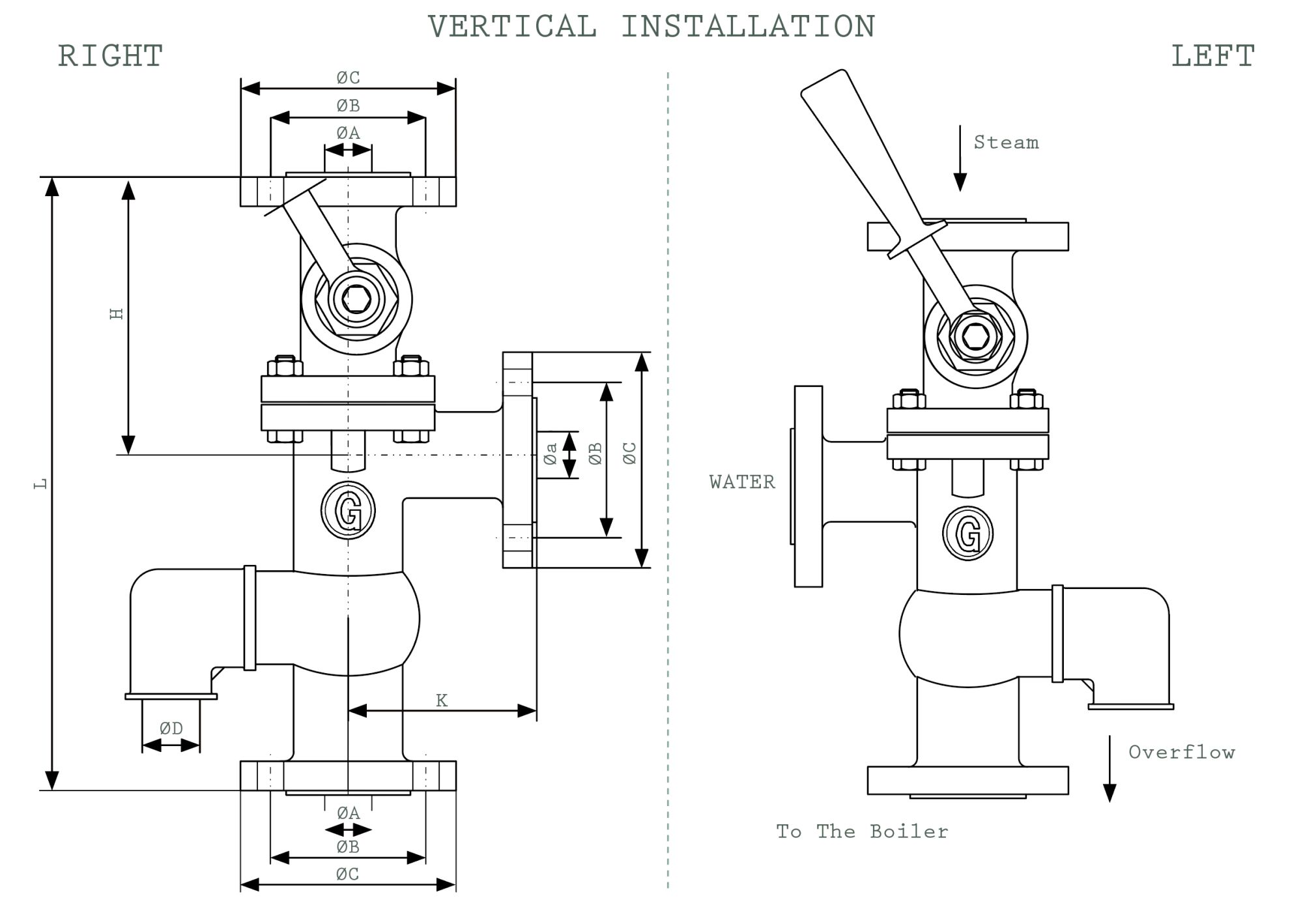

DIMENSIONS OF THE RESTARTING INJECTOR

| DN | DIM. | A | B | C | D | H | K | L | ||||||

| INCH | MM | INCH | MM | INCH | MM | BSP | INCH | MM | INCH | MM | INCH | MM | ||

| DN20 | 4 | 3/4 | 20 | 2 7/8 | 75 | 4 1/8 | 105 | 3/4 | 5 1/8 | 130 | 2 3/4 | 70 | 11 | 280 |

| DN25 | 5 | 1 | 25 | 3 3/8 | 85 | 4 1/2 | 115 | 1 | 6 | 150 | 3 1/8 | 80 | 12 3/8 | 315 |

| DN32 | 6 | 1 1/4 | 32 | 4 | 100 | 5 1/2 | 140 | 1 1/4 | 6 1/4 | 160 | 3 1/2 | 90 | 13 3/8 | 340 |

| DN40 | 8 | 1 1/2 | 40 | 4 3/8 | 110 | 6 | 150 | 1 1/2 | 6 3/4 | 170 | 4 1/8 | 105 | 15 | 380 |

| DN50 | 10 | 2 | 50 | 5 | 125 | 6 1/2 | 165 | 2 | 8 1/8 | 205 | 4 3/4 | 120 | 17 3/4 | 450 |

| DN65 | 12 | 2 1/2 | 65 | 5 3/4 | 145 | 7 1/4 | 185 | 3 | 9 1/4 | 235 | 5 | 125 | 20 | 510 |

| DN80 | 15 | 3 | 80 | 6 1/4 | 160 | 8 | 200 | 4 | 10 3/8 | 264 | 6 3/4 | 170 | 24 1/2 | 622 |